Badges are one of the most cherished embellishments carried from generation to generation. Truth to be told, they have been popular pieces even in Diagon Alley. The witches and wizards used these custom badges to show which house they belonged to whether Hufflepuff, Gryffindor, or Ravenclaw?

So, you must be intrigued to make your very 1st badge, but how?

Well, here in this blog, we have given an insightful junction over:

What are the types?

What is available backing?

Where are badges used?

And

What makes them so special?

TYPES

There are many kinds of badges available in the market. It’s simply up to one’s choice, whatever suits them or the nature of their business. The emblems happen to be of numerous kinds, from metal brass backings to stitched cloth ones.

Here we have tackled many streams for your ease.

Embroidered badges

Embroidered badges are one of the most popular ones. The sleek and matte finished look we get through the embossment of the threads is worthy to see. An ideal embroidered badge is stitched on the backside of the twill, giving it a three-dimensional look. The main character of the design appears to be embossed when seen through a naked eye.

Woven badges

Woven designs are weaved into one layer. There is no bump or any 3D outlook attached through it. It is slant and straight, giving it a flat posture. The woven symbols are quite durable and can stand machine wash with ease. There is no thread shedding or color bleeding, as the quality of the thread is always the finest. Woven marks are the most popular choice among rank holders because of their durability to stand the harsh weather. Custom woven badges in UK are quite famous.

Button badges

Button badges are one of the cheapest ones. They are usually created as a giveaway factor for advertising purposes. There is no thread or 3D printing involved in this genre. All they need is a plastic body with a metal pin holding the pieces together when pinned down on some cloth. The design is printed and sealed with a plastic lid for waterproof purposes. Like other insignia, you have the full liberty to design the coat of arms; you can choose whatever color seems a good fit for your theme.

Metal badges

Metal emblems are quite savvy and trendy. They are considered to be the elite class of all brooches. Sometimes they are protected with a shield of enamel coat, while others are drawn on a full structure framework. Ideally, they are worn by cult members or people following some hard-core group.

BACKINGS

The next step is to look for the backing options; here, we have explained every possible backing for your badge.

Plastic

This is one of the most basic backings used by default, it comes with every badge. It is no need to be particular because this thin layer of plastic works with every medium. Whether it is woven, embroidered, or painted. This backing helps the badge retain its shape and withstand simple machine washing without losing its framework.

Heat seal

Heat seal backing is widely used because of its easy usage purpose. This backing is activated when an iron hits warmness on the badge. When the heat insulates through the emblem, the glue is activated, making the surface well lubricated to attach to the exterior more easily. The only problem with this patronage is that it cannot stand many washes and can damage if the surface of iron directly hits on its face.

Velcro/ Hook and loop

The Marines mostly use Velcro backings, counterparts of two components: hook and loop. The military badges are assigned under this backing because they are easy to place and can be easily replaced. They are machine wash friendly. They don’t lose their adhesiveness. They are usually curated, keeping in mind the higher authority generals.

Self-stick/ peel away.

Self-stick is made with sticky adhesive backing. All you have to do is to peel the paper; paste/sticks it wherever you want. But, do remember it only sticks one time. If you keep changing the surface, it will loosen up its adhesiveness. It is advisable to 1st mark the surface, then stick your badge on that surface.

Clutch pins

Clutch pins are one of the most exquisite and high-grade insignia. They are mostly given according to the ranking promotion or a prestigious title. This backing is also used when you don’t want options like sewing, sticking, or Velcro. This selection is considered the easiest one, and there is no wear and tear attached. This backing is fully backed with custom brooches, making it an all-rounder in the field.

Magnetic

Like pin backing, magnetic backing is also comprised of a pin-like texture. One segment is attached on the cloth side while the other piggyback it. When you want to attach it to some apparel, simply unwind the tab and place it wherever you want by securing it with a magnetic field. Magnetic insignias are quite versatile and can be used in several ways, like on woven name labels.

How badges are used

- Worn on clothes to show the funky side.

- Personalized ones are used to carry a message.

- Often charities and fundraisers are associated with it.

- Add a unique quotient.

- Enhances boring old apparel.

- They can be used as easy football badges

- Add it to your backpack to make it stand out among the crowd.

- Most famously used in denim jackets.

- A higher rank or authority is reflected upon it.

There are several ways through which you can use and show your love and how to don it.

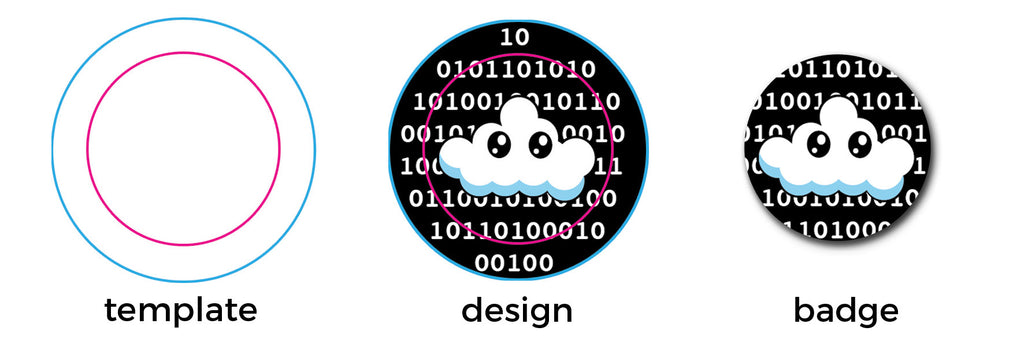

Three ways to make your badges right from scratch

Inkjet pictures

Inkjet pictures are one of the easiest ways to make a badge at home. All you need is the fabric you want to paste on your badge work. A drawing or a design, and one more thing is an inkjet transfer sheet.

1st you will scan the drawing or simply download it; after that, you will resize and adjust it according to your need. After that, you put the inkjet transfer sheet into your printer and simply print it. When you get the result, peel on the backside of the sheet and stick it onto the fabric, and with the help of an iron, heat press it. The pressure will allow the pattern to adhesive more effectively. After 5 minutes, remove the peel, and VOILA! Here is your own custom-made badge right from scratch.

Hand embroidery

This method needs some training and hands-on experience. Because you have to master the basic stitches when doing the needlework, all you need is some threads, needles of various sizes, a design blueprint, and a wooden frame. You need to follow some pointers while sewing keeping the alignment right.

Faux machine embroidery

It will give you a quick fix, but it will not give a sleek dimensional detailed look like embroidery. This can be achieved through a zig-zag needlework attachment in the sewing machine. The deal is that you have to make the design in a geometric pattern so it can be easily transferred on a machine pattern.

Concluding thoughts

Badges are one of the unique ways through which you can show your personalized style. They have the tendency to enhance any damn boring piece into an electrifying one. Through this article, we have given every minute detail regarding the types, the backing materials available in the market, and how you can create badges right from the comfort of your home. You can use the three prescribed methods without purchasing any heavy-duty machinery. The inkjet is one of the easiest, and embroidery can intimidate a little because a prior skill and hands-on experience are needed.

So pick away whatever design or pattern entices you and shape that into one perfect badge!